An oilfield worker who filed suit after being hurt on the job in 2017 when a well desanding unit failed has scored a partial victory to move ahead with his suit in Oklahoma City federal court.

Devin Wayne Loomis was injured June 10, 2017 as he operated a desander unit attempting to remove sand from drilling fluids on a well located in Kingfisher County. The desander had been leased from Specialized Desanders USA, Inc.

U.S. District Judge Robin J. Cauthron ruled in support of SDI’s motion to dismiss the product liability claim made by Loomis. But the Judge ruled against SDI in its effort to dismiss the negligence claim.

The suit by Loomis contended the desander was negligently designed and distributed with an unsafe and defective threaded nipple. The rulings mean the case can go to trial unless there is a settlement reached between the two sides.

Loomis said he was left with permanent injuries as a result of the incident. He was operating a desander unit and was hurt while attempting to blow the pressure down when a threaded nipple on the desander dislodged causing a sudden release of pressure.

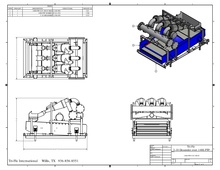

Desanders and desilters are solid control equipment with a set of hydrocyclones that separate sand and silt from the drilling fluids in drilling rigs. Desanders are installed on top of the mud tank following the shale shaker and the degasser, but before the desilter. Desander removes the abrasive solids from the drilling fluids which cannot be removed by shakers. Normally the solids diameter for desander to be separated would be 45~74μm, and 15~44μm for desilter.[1]

A centrifugal pump is used to pump the drilling fluids from mud tank into the set of hydrocyclones.